Inconsistent repair abbreviations create confusion and inefficiency in the R&M sector. This guide provides a step-by-step plan to standardize your abbreviations, leading to improved data analysis, enhanced communication, and better decision-making. Let's address this common problem and unlock the full potential of your R&M data.

The High Cost of Inconsistent Repair Shorthand

Different repair abbreviations (e.g., "R&M," "RM," "RSU") create confusion and hinder effective R&M data analysis. This isn't just about neatness; inaccurate data leads to poor decision-making, impacting maintenance planning and resource allocation. "Misinterpreting abbreviations wastes valuable time and resources," says Dr. Anya Sharma, Lead Data Scientist at Predictive Maintenance Solutions. The cost of this inefficiency can significantly impact a company's bottom line. Isn't it time to fix this solvable problem?

A Practical Plan for Consistent Repair Terminology

This six-step plan helps standardize your repair abbreviations. The suggested implementation includes data migration and ongoing monitoring to ensure long-term consistency. Following this plan will drastically improve data quality and efficiency.

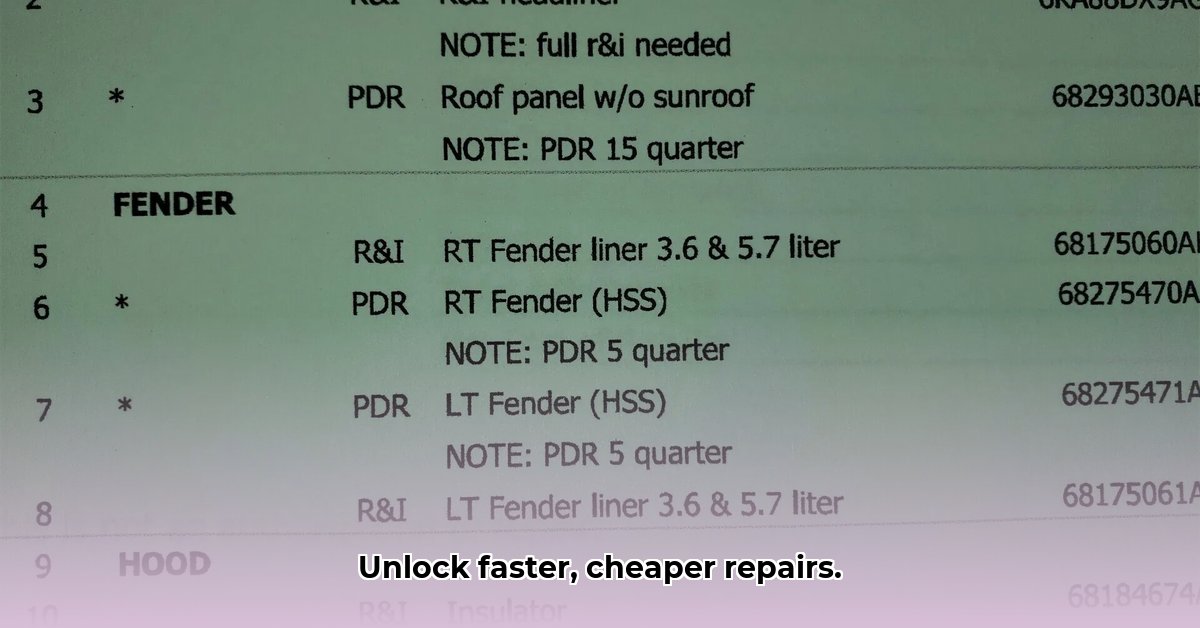

Inventory Existing Abbreviations: Thoroughly review all documents, reports, and software to identify every repair abbreviation currently in use. Note each abbreviation's context and usage. This inventory provides the baseline for standardization.

Choose a Single Standard Abbreviation: Select one clear, easy-to-understand abbreviation for company-wide use. Consider industry standards for broader compatibility. Simple is best; avoid ambiguity.

Comprehensive Staff Training: Conduct interactive training sessions (videos, hands-on exercises) to ensure all staff understand and adopt the new standard. Address any questions or concerns to gain full buy-in. A well-trained workforce is vital.

System-Wide Implementation: Update all reports, software, databases, and training materials to reflect the standardized abbreviation. Consistency across all systems is key to success. Ensure complete integration.

Data Migration and Cleansing: Carefully update existing data to reflect the new standard. This might involve manual review, data scrubbing tools, or a phased approach. Accurate data is crucial for reliable analysis.

Ongoing Monitoring and Audits: Regularly audit data and processes to ensure continued adherence to the standardized abbreviation. Address any emerging inconsistencies promptly to prevent future issues. Proactive monitoring prevents regressions.

Teamwork Makes the Dream Work: A Collaborative Approach

Standardizing repair abbreviations requires a collaborative effort across departments. This table outlines short-term and long-term actions for key stakeholders:

| Stakeholder Group | Short-Term Actions | Long-Term Actions |

|---|---|---|

| R&M Management | Officially adopt a standardized abbreviation; enforce its use. | Champion industry-wide standardization; actively participate in relevant initiatives. |

| Data Analysts | Update datasets and reports to reflect the new standard. | Develop automated tools to detect and correct inconsistent abbreviations. |

| Software Developers | Update company software; ensure compatibility. | Collaborate on developments to ensure data compatibility across systems. |

| Regulatory Bodies | Review and clarify reporting guidelines to promote standardization. | Create standardized reporting protocols for industry adoption. |

Managing the Risks of Inconsistent Abbreviations

Inconsistent abbreviations pose several risks. This matrix details mitigation strategies:

| Risk Factor | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Miscommunication from inconsistent shorthand | High | High | Standardized abbreviation, thorough training, and regular communication. |

| Inaccurate data and reporting | High | Medium | Data cleansing protocols, regular audits, and data validation checks. |

| Regulatory non-compliance | Medium | High | Proactive compliance with evolving guidelines and internal audits. |

| System incompatibility due to variation | Medium | Medium-High | Software updates, data interoperability solutions, and compatibility checks. |

How to Standardize Repair Abbreviations for Improved R&M Data Analysis

Standardizing repair abbreviations isn't merely about aesthetics; it significantly improves R&M data analysis. "Consistent terminology is the cornerstone of accurate reporting," notes John Miller, Maintenance Manager at Global Power Systems. By eliminating ambiguity, we facilitate better decision-making, leading to increased efficiency and cost savings.

Key Takeaways:

- Inconsistent abbreviations hinder effective R&M data analysis, potentially leading to costly errors and delays.

- Standardization dramatically improves communication, data integrity, and the efficiency of reporting.

- A well-defined and consistently implemented glossary of abbreviations is crucial for success in this initiative.

- Regular audits and ongoing monitoring are essential to maintain the integrity of the standardized system.

- Collaborative effort across teams and departments is vital to ensure a seamless transition and long-term success.

Conclusion: Reap the Long-Term Benefits

Implementing a standardized system for repair abbreviations delivers significant long-term gains. By investing time and effort now, you create a more efficient, reliable, and informed R&M operation. The improved data analysis, streamlined workflows, and better decision-making will far outweigh the initial investment. Embrace this change and transform your R&M processes.